Falcon Transfers Reviews

Real Customer ReviewsAt Falcon, we know every print matters.

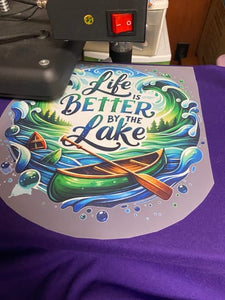

That’s why our DTF transfers deliver consistent quality, vibrant color, and reliable performance — helping you sell more with confidence.

Wondering Why Us?

Frequently Asked Questions

What is a DTF transfer?What are your business hours?

We are open Monday to Friday, 9 AM – 6 PM, and Saturday, 9 AM – 3 PM. We are closed on Sundays.

When will my order be ready / When will it ship?

Orders placed before 12 PM are eligible for same-day shipping or same-day pickup.

Orders placed after 12 PM will be ready the next business day.

Do you offer express or same-day shipping?

Yes! If you place your order before 12 PM, it will ship out the same day.

Do you offer custom prints?

Yes! You can upload your own designs through the DTF Builder or use the “Upload by Size” option, and we’ll print them for you.

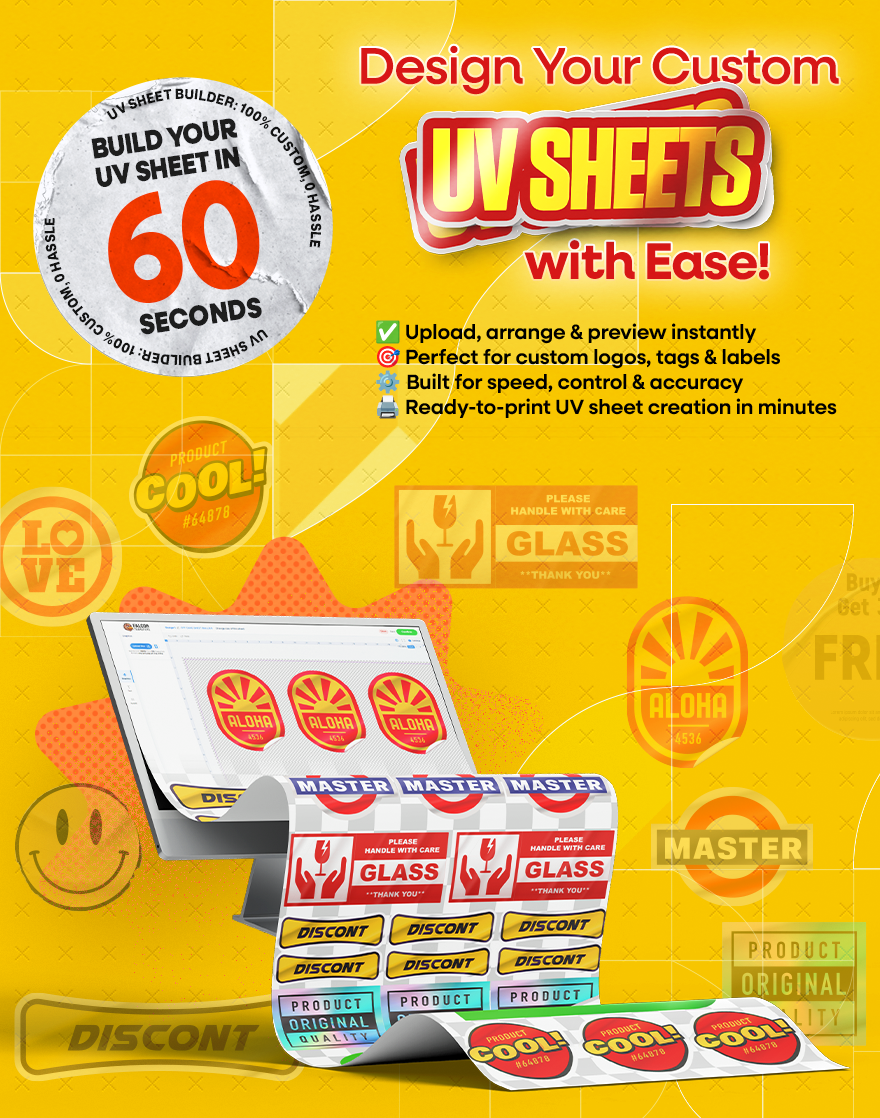

What’s the difference between Option 1 and Option 2 in the DTF Builder?

Both are gangsheet builders used to arrange your designs on a sheet. They serve the same purpose — the only difference is the software interface. Customers can choose whichever feels easier.

What is included in a sample pack?

Our sample pack includes a variety of transfers (different sizes, colors, and effects) so you can test quality and application on different garments.

Can I send my own designs for a sample pack?

No, sample packs are pre-made. To test your own artwork, you can place a small custom order.

What file formats does your website accept?

Our website accepts AI, PNG, PDF, and SVG files. (JPG/JPEG is not supported.) For best results, we recommend transparent PNG at 300 DPI.

Is there a minimum order requirement?

No, there is no minimum order — you can even order a single small transfer.

Can I print metallic colors?

No, metallic and specialty inks (like glitter or foil) are not available with DTF.

Do I need a heat press, or can I use a regular iron?

We strongly recommend a heat press. Household irons or small craft presses cannot provide the consistent heat and pressure required for proper application.

What is a DTF transfer?

Direct to Film (DTF) transfers are a modern way to print full-color, high-detail designs that can be applied to a wide variety of fabrics, including cotton, polyester, and blends.

Best DTF Transfers in Canada